General:

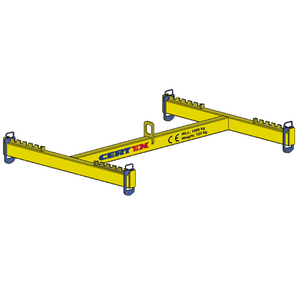

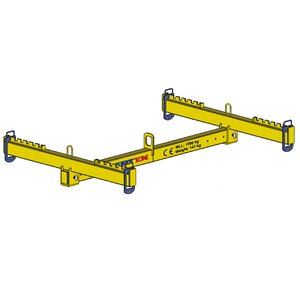

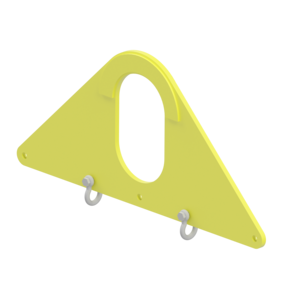

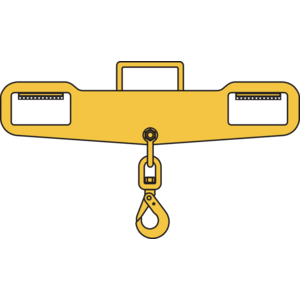

Lifting beam in different varieties is often a necessary tool for lifting. The concept also includes lifting beams spreader, lifting triangles and a variety of combinations and special structures in order to balance the load and distribute the load on multiple lifting points. It is impossible to standardize all the different models available and therefore only a minor part of our range are presented in the catalogue. Other types, configurations, combinations and solutions are designed and manufactured to order.

Design:

We design, construct, calculate and manufacture products that meet the requirements of the Machinery Directive 2006/42/EC and we are using standard EN 131 55. Construction verification can be done with proof loading, FEM analysis, enhanced strength calculation and simulation according to the user needs.

We also work in accordance with the following standards and requirements according to customer needs:

DNV 2:22 / DNV 2.7-1 / DNV 2.7-3 / NORSOK R-002 / ASME B30: 20 / KTA 3902 / AFS 2023:4 / AFS 2023:11 chapter 4, etc.

Manufacturing:

The lifting beams are manufactured by experienced staff and all welding work is performed by licensed welders according to EN ISO 9606-1:2013. Welding is performed according to EN ISO 3834, selected part depending on customer requirements.

Labelling: According to the Machinery Directive 2006/42 / EC and any customer requirements.

Tests: 2 x maxiumum load according to EN 131 55

Accessories:

For the lifting beams accessories such as shackles, hooks, steel wire rope slings , chain slings or synthetic slings are used, depending on the application and requirements. For more details about the tools we refer to other parts in the catalog. Many times it can be of interest to use stands, storage or transport solutions, which can be designed and manufactured to order.

- Finish: : Yellow painted RAL 1003, other surface treatment upon request.